Research & Development

At the R&D center, we create and develop new products, test new applications of biocellulose, and modify the material tailored to the customers’ needs. A creative team of experts and experienced professionals allows us to improve the technology and scientific research methodology, conduct theoretical analysis and systematic studies of our material.

Biocellulose is an excellent natural biomaterial with unique features that will find a special place on the biomedical market. Advanced manufacturing processes and technologies are the result of cooperation and exchange of experience with global experts. We are currently participating in scientific research projects on the application of biocellulose in reconstructive and regenerative medicine.

CARDIO BNC PROJECT

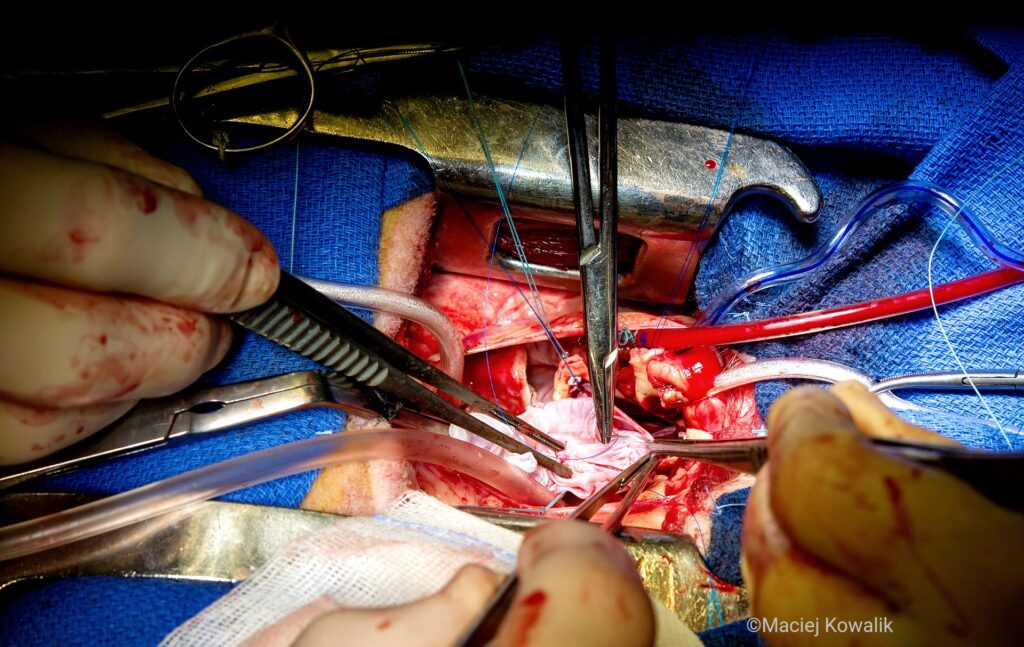

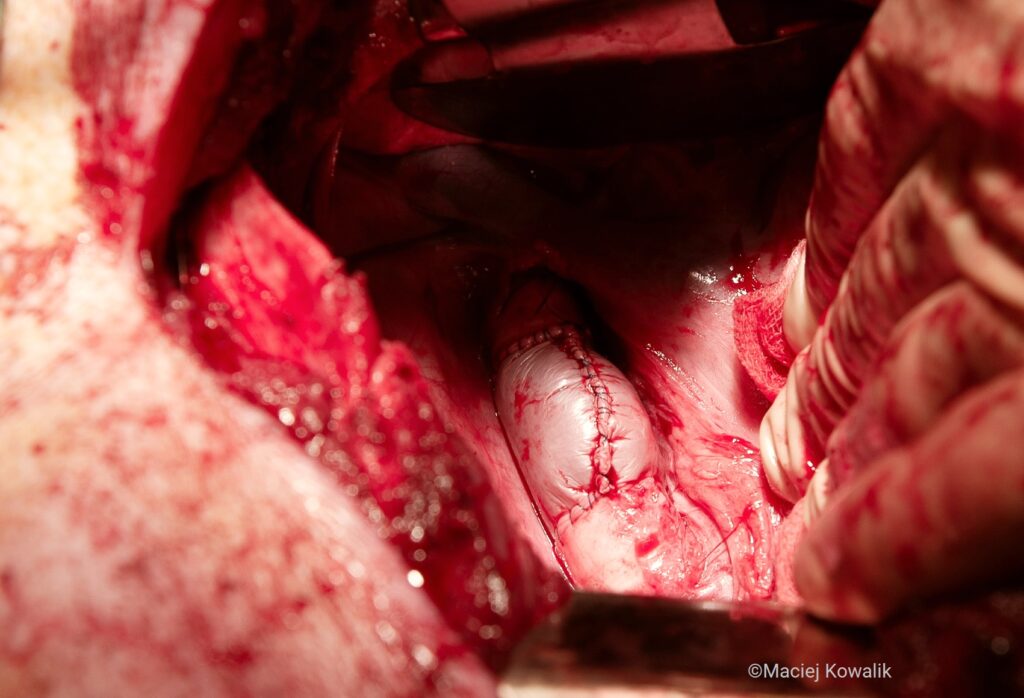

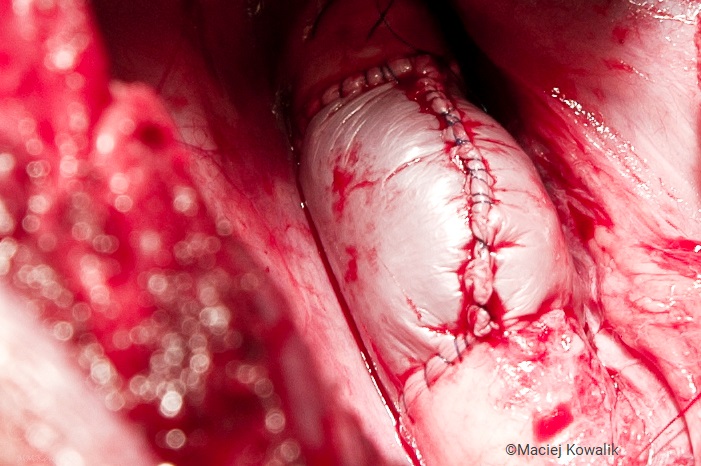

Under the Second Applied Research Program of the National Research and Development Center, with other scientific units, we co-develop a project based on conducting preclinical studies of the bioimplant applicability, used in cardiac and vascular surgery.

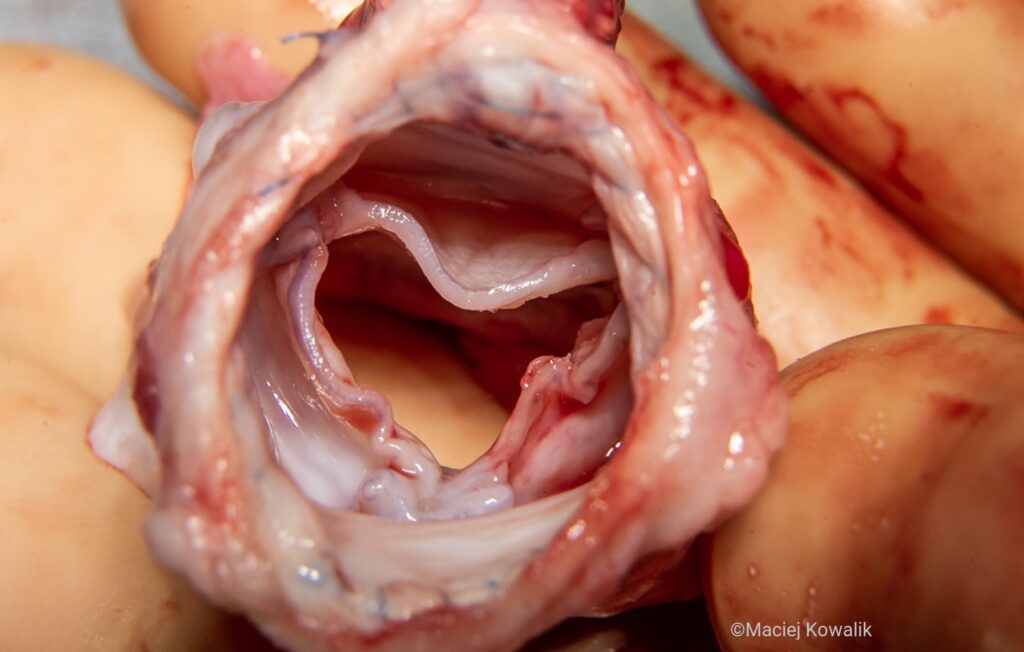

As a part of the consortium with the Medical University of Gdańsk, leading by the Head of project Piotr Siondalski, MD, PhD, we strived to develop a bacterial cellulose used as a biocompatible material for human cardiovascular system. The project was based on mechanical, biochemical, biostability and biocompatibility studies of biocellulose, in vitro and in vivo tests of vascular prostheses models, pericardial patch, pulmonary heart valve and aortic valve. The bioimplant is currently undergoing preclinical studies.

PORYBY 4.1 PROJECT

Participation in the project gave us the opportunity to business development by launching the Medical Research and Training Center. The program also aimed to demonstrate and popularize the unique healing properties and wide BC application among health professional and the local community.

KAD-TECH PROJECT

As part of the project co-financed by the National Center for Research and Development, we conducted research on the development of biocellulose analgetic dressing for the treatment of patients after hemorrhoidectomy. For this purpose, we have established cooperation with physicians dealing with postoperative pain issue and commissioned research work to the Faculty of Pharmacy of the Medical University of Gdańsk.

Biocellulose has unique features that distinguish it from other materials used in cardiac surgery

densely woven nanofibers network holds > 95% of water

low immune response of material, coverage by healthy endothelium

atrombogenic surface, no hemolytic activity

superior sealing quality, impermeability to blood cells

high plasticity material, suture retention strength

free of pyrogens material

high durability, non-resorbable in vivo

calcification-resistant material, high fatigue strength

low prion transmission, no infectious agents from animals

hypoallergenic, biocompatible material

no cytotoxicity or genotoxic effects

excellent handling properties of biomaterial

Scientific materials

In search of the ideal biomaterial

Learn more

In search of the ideal biomaterial

Learn more

In search of the ideal biomaterial

Agata Humelt, PhD, Bowil Biotech Sp. z o.o.The full white paper by clicking the link: In search of the ideal biomaterial

Bacterial cellulose properties

Learn more

Bacterial cellulose properties

Learn more

Bacterial cellulose properties fulfilling requirements for a biomaterial of choice in reconstructive surgery and wound healing

J. Jankau, A. Błażyńska-Spychalska, K. Kubiak, M. Jędrzejczak-Krzepkowska, T. Pankiewicz, K. Ludwicka, A. Dettlaff, R. PęksaThe full article by clicking the link: Frontiers in Bioengineering and Biotechnology, 9 (2022) 805053

Bionanocellulose composites

Learn more

Bionanocellulose composites

Learn more

Bionanocellulose/poly(vinyl alcohol) composites produced by in-situ method and ex-situ impregnation or sterilization methods

A. Długa, J. Kowalonek, H. KaczmarekThe full article by clicking the link: Materials (Basel), 14 (2021) 6340

Assessment of the usefulness of bacterial cellulose

Learn more

Assessment of the usefulness of bacterial cellulose

Learn more

Assessment of the usefulness of bacterial cellulose produced by Gluconacetobacter xylinus E25 as a new biological implant

M. Kołaczkowska, P. Siondalski, M. M. Kowalik, R. Pęksa, A. Długa, W. Zając, P. Dederko, I. Kołodziejska, E. Malinowska-Pańczyk, I. Sinkiewicz, H. Staroszczyk, A. Śliwińska, A. Stanisławska, M. Szkodo, P. Pałczyńska, G. Jabłoński, A. Borman, P. WilczekThe full article by clicking the link: Materials Science and Engineering C, 97 (2019) 302